Pertamina Balikpapan

The Balikpapan refinery has upgraded its capacity by almost 40% and added a Fluid Catalytic Cracking unit with a dual driven compressor, power recovery turbine and SSS Clutch to improve energy efficiency and process reliability

The Balikpapan Refining Development Master Plan (RDMP) is a project by PT Kilang Pertamina Internasional (KPI) to upgrade and expand the Balikpapan refinery in East Kalimantan, Indonesia.

They have increased crude oil processing capacity from 260,000 to 360,000 barrels per day and enhanced product quality to meet Euro V emission standards. Key aspects of the project include adding a Fluid Catalytic Cracking (FCC) unit and revamping existing facilities to improve refinery complexity, product value, and national energy security.

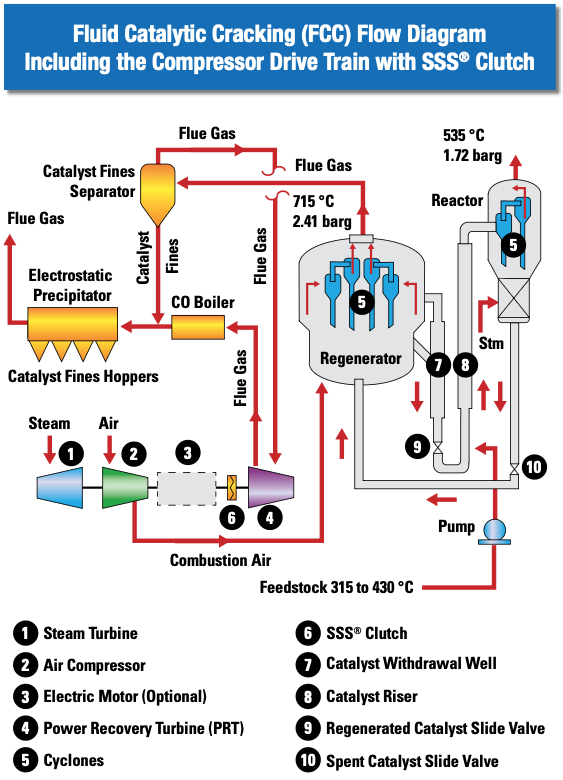

The FCC drive train includes a Power Recovery Turbine (PRT) which recovers energy from the flue gas from the FCC process to deliver all or most of the power required to drive the compressor providing air for the fluidized bed in the FCC reactor. The turbomachinery drive train includes a 23MW size 140T Encased SSS Clutch operating at 3600 rpm arranged as - PRT Expander - SSS Clutch - Axial Air Compressor - Steam Turbine (see below).

The FCC converts heavy oil feedstock to lighter components for the production of gasoline. The flue gas is a by-product of the reaction and is a combination of carbon monoxide and hydrocarbon gases which is fed through the PRT to a boiler where it is used as fuel to produce steam.

Due to the corrosive nature of the flue gas, the PRT typically has a shorter maintenance interval of 2 to 3 years vs the other drive-train components which can often operate non-stop for 5 years. Process upsets can further shorten the PRT maintenance interval, with failures generally due to imbalance caused by the buildup of contaminants on the rotor or corrosion stress cracking of the turbine blades.

The addition of the overrunning SSS Clutch to the drive train provides operational flexibility, allowing the PRT to be shut down for maintenance independent of the air compressor and steam turbine. Depending on how the steam turbine is sized, the train may be able to run at full output with the PRT shutdown. With an SSS Clutch included, the PRT can be repaired while the compressor train continues to run, and after the repair, it can be re-started and re-engaged with the already running compressor train.

The FCC unit is the primary producer of petroleum products in a refinery and an unplanned shutdown of the associated FCC compressor unit can cost over $4 mill per event. The recovered power from a 23MW PRT added to the compressor train can be valued at over $10 mill per year, so the ability of the SSS Clutch to disconnect a problematic PRT and permit the FCC compressor train to remain operational via the secondary driver is extremely valuable.

Also if a hard coupled PRT is used with no clutch, and there is a catastrophic failure during operation, there can be safety concerns for plant personnel who may be in the vicinity of the machine.

These operating characteristics of the PRT make it easy to justify using an SSS Clutch as a disconnect for the PRT in the compressor drive train and as SSS Clutch technology is known for its high-power capability and reliability, it is ideally suited for this dual driven compressor application.